Sam's Proper MX-3 - LT Turbo project *Parting out*

-

Really want to copy that gril if you don;t mind. As mines black i think i'd use red tubing round the hole. Is there any reason you didn't just connect the bottom grill to the top one to make it even bigger?

-

I dont mind mate :D the tubing is 5mm silicon vacuum hose

split up the side.

So like this?

bumper would be extremely flexible when cutting that out

(it could easily fold in half)

without some serious bracing involved, you would expose

alot more of the black bumper support and it would be even

harder to put some nice grill mesh in there…. but dont let

any of that stop you, if thats what you want it to look like :)

-

pretty sure its not worth that. Think yours looks better anyway.

-

ar thanks Jim, I didnt want say it was a bit ott

just in case….Thanks Marco for this pic :D

-

Alright folks, nice little development on the

turbo front here. Just spent 3 hours @ the breakers

Found an MX-3 removed the radiator, then spent

the next 2 hours 45 minutes looking at nearly every car radiator

in there! until I found this :D

Boost pipes will easily fit past the radiator now, making

the intercooler set up so much easier.other development taking place this weekend are coralating

my car ECU loom with the schematics I have from .com, to make sure

there the same so I can then send them off to Boomslang to make the harness.

1/3 of the way there to buying the SPEC stage 2 clutch I also require.Will do the rad first, then probaly the clutch(remove egr while im there), then get the AEM + boomslang up and running, once all those mods are proven good and working, I can start thinking about putting on the turbo, injectors and intercooler.

-

Excellent, looking forward to this build

-

Me too!

someone was aking for a shopping price list for this Turbo conversion

so here goes:323 Turbo manifold >10

323 Turbo baffled sump >5

IHI VJ-11 Turbo >90

AEM F/IC ECU >280

Boomslang harness >110

wideband lambda > 130

SPEC clutch >200 +100 delivery

Injectors > 20

Boost pipes/joiners/silicon elbows > 30 - 80

hose clips > 20

Intercooler > 10 - 100

Oil lines > 20

Water lines > 20

Boost guage > 30

Exhaust flexi > 20

sundries > 40Say about 1K is a good estimate there, not including a mapping session

as we are going for a street tune to begin with 8)

-

Ok after alot of studying and researching

diagrams yesterday, we are proposing to

make our own boomslang patch loom, saving

a good £££, it dosent look too difficult.wiring schematics from .com we are going to assume are

the same, will test all the ECU pinouts just to be sure though,

the 95-98 1.6 MX-5 ECU pinouts are the same, bar a few discrepencies!So if our loom is a succes, we maybe able to do others for the 1.6

AEM install.

-

Started making this today > its going to be a header

tank for the new rad. install.

-

Looking good,

maybe some nice polished battery cases are on the cards too if you get any spare time :wink:

-

cant do them, there not circular :lol:

The 'shop round the corner have alot of benders though :wink:

-

I knew that i didn't have the funds to do the 1.6 turbo but now i'm pretty damn sure i don't have the know-how to do this.

-

@816df7e8c0=youdirtyfox:

The 'shop round the corner have alot of benders though :wink:

Umm, hairdressers?

-

@6bc6cb934c=JIMBOfred:

I knew that i didn't have the funds to do the 1.6 turbo but now i'm pretty damn sure i don't have the know-how to do this.

You can learn the knowledge from here Bro :D

it is a case of quite a bit of research and reading

check the FAQ's from garrett I posted up also.This is my second Turbo conversion, so I've learnt alot from the first

but before that I hadnt really tinkered with cars that much.

-

I workied on heavies for a couple of years but was mainly servicing and so turbo's are a little still a bit alien to me.

-

you'll be fine then, its just understanding the concept

of 'forced induction' next.

@3846eb1d4e:

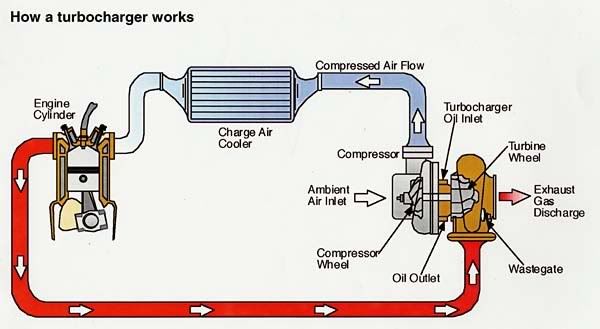

A turbocharger is used to force air/fuel mixture into an engine at a pressure greater then the natural atmospheric pressure of around 14.5 PSI. When a turbo produces 7 PSI of boost, this means how much extra pressure it applies on top of the natural atmospheric pressure. The way a turbo works is the exhaust coming out of the engine is pushed through a turbine. This turbine is mounted on a shaft, which in turn spins an air compressor. The compressor draws air in and blows it into the inlet manifold, and this produces BOOST. The whole point of forcing the air/fuel mixture into an engine is to allow it to burn more fuel and make more power with the same engine capacity. This can get complicated, as there are several factors that get in the way of efficency gain. For one thing when you compress air (with a turbo) it gets hotter. The problem with hotter air is that it contains less oxygen than cooler air, so there is less oxygen to help burn extra fuel that’s going into the engine. This is why many turbocharged cars use “intercooling” of various types, to cool the pressurised air back down into the engine.

-

@3fdcd893f8:

It’s important to consider problem of too much heat inside the engine. Once the hot compressed air goes inside the engine it is then compressed again by the piston in the engine. Therefore by the time the mixture of fuel/air mixture is ignited it is really hot. When it is too hot it could ignite itself before the spark plugs fires (known as pinging). When the engine pings the smooth, well-timed normal ignition mishaps, costing you power and damaging ports to the engine. Damage is caused to the engine, and can therefore lead to blowing the head gasket, this then chain-reacts to more severe cases. Another problem when the engine has an air/fuel mixture which is too lean, that is not enough fuel for the air coming in, which creates too much heat, or having ignition which is not suited to the engine. With private turbo installations these problems are often ignored. The ignition timing required for optimum power and smoothness from a turbocharged engine is in fact totally different to that required for a non-turbo engine. This is because the more efficient the engine is, the less advanced the ignition timing needs to be to get power combustion of the fuel/air mixture. When the engine gets more and more boost, the ignition should happen later and later in each cylinders or rotors combustion cycle. To get best out of the turbocharged engine it needs a balance of boost, mixture richness, charge air temp and ignition timing that allows it to run smoothly and efficiently with the type of fuel you're using. If you use low-octane fuel, it is more susceptible to pinging as it ignites more suddenly and erratically. The higher the octane of your fuel, the more smoothly and progressively it will burn, which helps prevent pinging. This means that with better fuel you can run more boost or more advanced ignition without any engine difficulties, which indeed means more POWER.

So the piggy back ECU ( meaning its run in harmony with the stock ECU)

supplys more fuel by holding the injectors open for longer (along with larger injectors) and re-tards the ignitionwhen on boost. The Turbo shaft is lubricated with oil and cooled with water,

so you need to supply it with both, high pressure oil line can come from

the oil pressure switch, or in the case of the B6 engine it already has a tapped hole in the side of the head to use and it drains back into the sump after the turbo, the water connections can come from the top radiator hose and drain back

into the bottom radiator hose. Intercooler for cooling the charge down, and uprated clucth to handle more torque that the engine produces. The wideband lambda sensor is to keep an eye on the Air/Fuel ratio, and the boost guage keeps an eye on the boost pressure being generated.Hope this helps :)

-

Did a bit more today on the header tank,

waiting on the filler neck & rad cap to arrive, bit

more welding and polishing and she'll

be good to go :D

-

Factory shutdown! so Im on Holiday now!! :D 8)

Cant finish the tank now though :(

Needed to do a bit of sussing out anyways…

thinking clear filler hose or see through green hose

would look quite mental.

Slim line 12" rad fan on order, to make even more room,lol

Been checking how straight I can get this boost piping, less

bends the better as they generate more heat…

be back soon with full rad install :)

-

Drooling dude, sooo shiny 8) 8)