Jono's KLZE Project - Turbo Build Begins

-

So 8 years after my ZE swap the engine is back out of the car as I actually start the turbo build!

Managed to get it out much faster than the first time and I had no assistance this time! :D Although I did take a nice breaker bar to the knee thanks to a rusted bolt! :shock:

The bay looks a little empty right now but plenty of work to do here. I made a small mistake when releasing the power steering belt tensioner, I forgot to loosen the retaining nut and broke the metal work so looks like I need a new tensioner - if anyone has one please let me know.

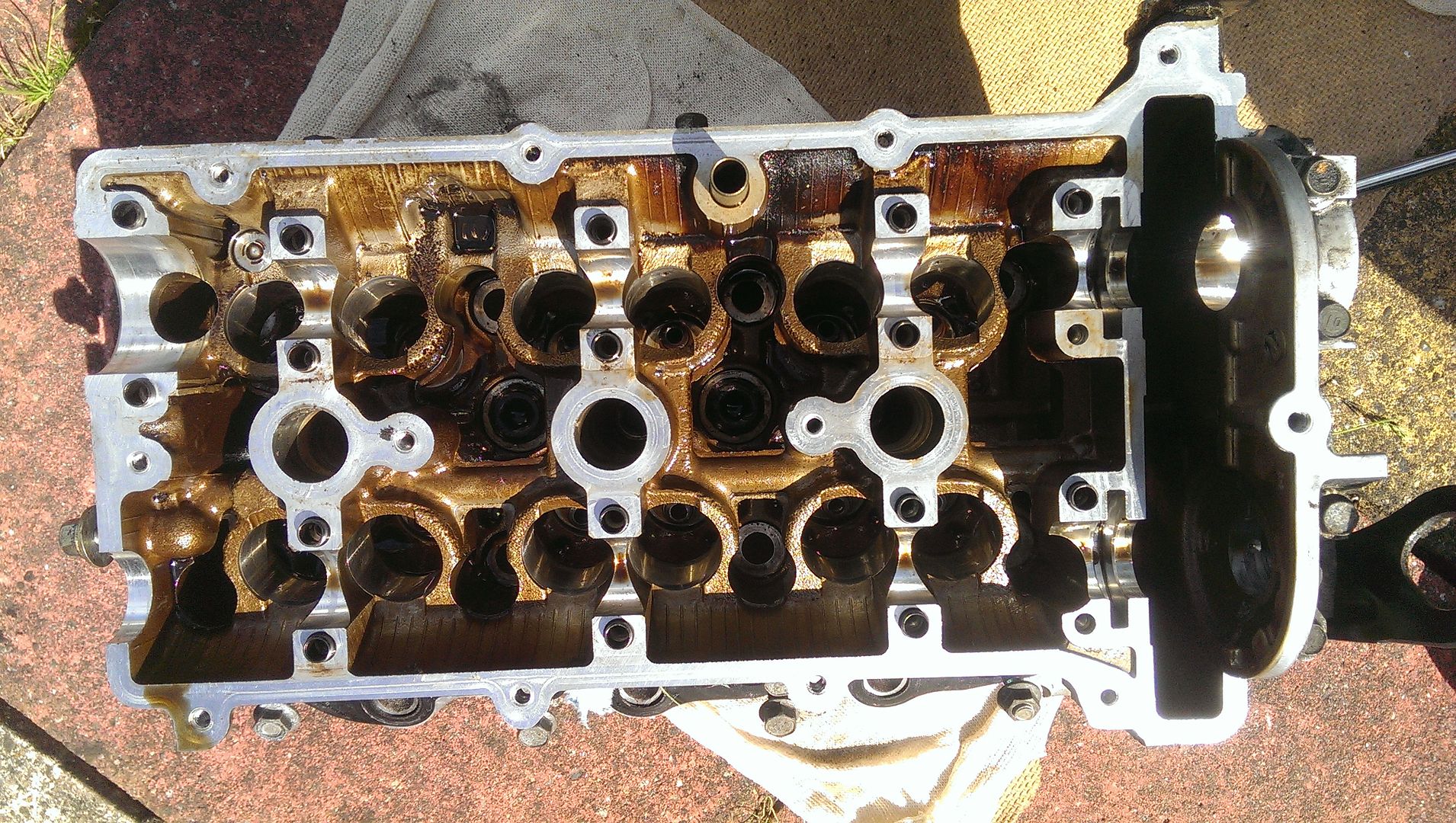

I've started to tear down the engine earlier then expected as I need to know the bore size for the custom Wiseco pistons I want to order.

Unfortunately it looks like my cam's have seen better days, so that's more money I need to spend.

Also looks like I might have some water in there, hopefully thats not caused by anything too serious!

Will keep you updated

Jono

-

You could probably just polish up those cam surfaces. Doubt you'd lose much from it!

Great to see some progress :bigok:

I bet you £20 it's standard bore 84.5 ;)

-

Flaming crankshaft pulley!!!! What a pain that was to remove without a holding tool.

So I'm getting there slowly with the tare down, hopefully if I get time I will have the head off by the end of the week.

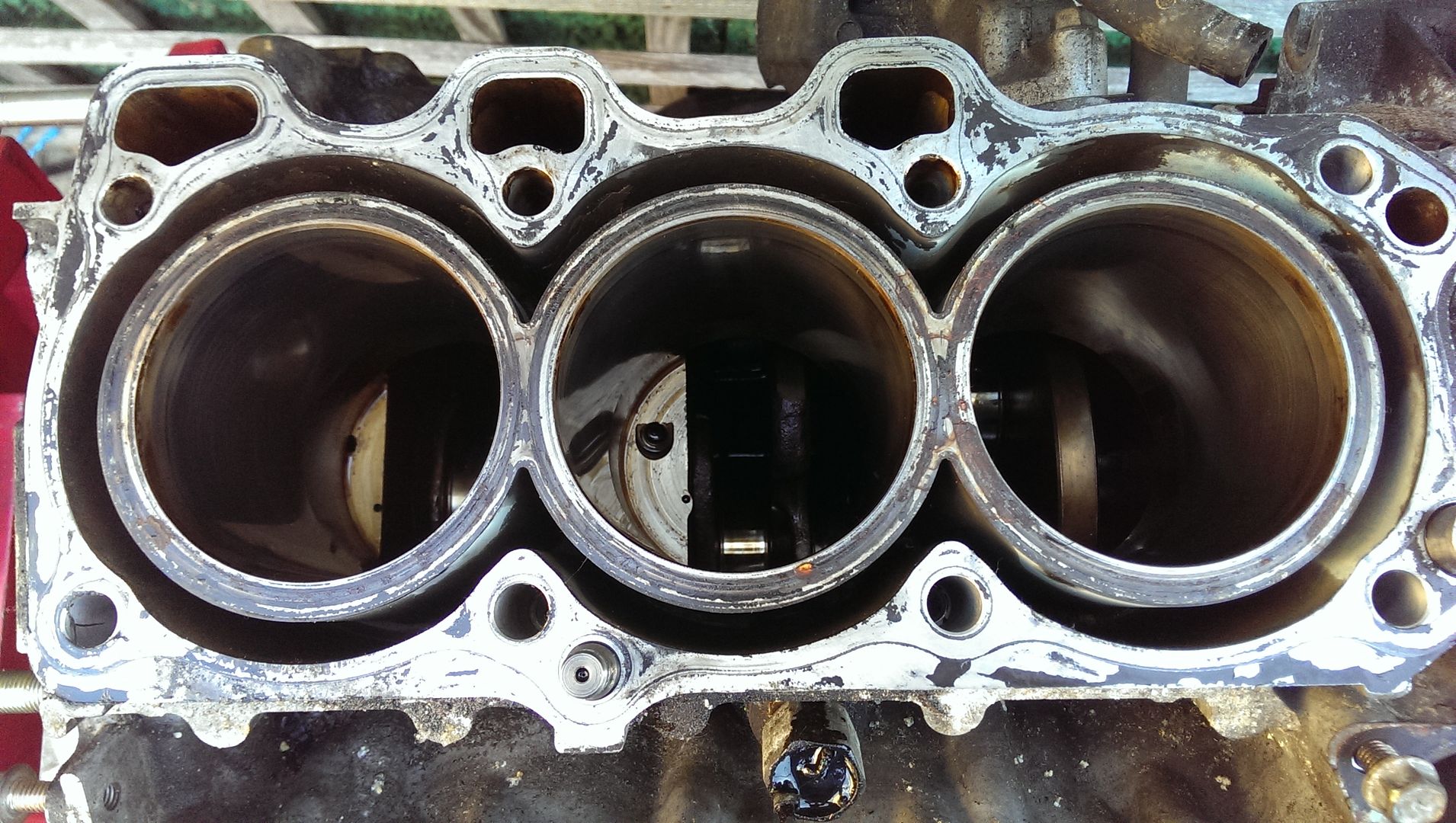

Interestingly the company I am getting the internals from thinks I will need a re-bore an sleeve on the cylinders, can anyone shed any light on this, is this normally needed, can I not just replace the existing pistons without doing anything with the block?

Jono

-

Haha easiest way is with engine still in car, breaker bar leaning against the ground and crank it for a second.

Rebore and sleeve? I doubt it. More likely just need a hone unless it's out of round. Sleeves are cast iron. As long as you don't go too big no need to resleeve.

For my rebuild I just bought a hone tool for a drill and took off the glaze myself.

-

Ok, so guess what… the bore size is standard :D

I now have all of the new internals on order, that should take a few weeks before I get my hands on them, so I plan on stripping the rest of the engine and hopefully get it to the engineering workshop for some work.

I'm also thinking I might do the short shifter upgrade as everything is easy to get to, who has one? where did you get it from?

Also, I want to upgrade the breaks but the only kit I can find is too expensive really, its £1500 just for the fronts!

I noticed early on with the MX3 that it has the same caliper arrangement as an old ford escort, has anyone tried an escort break upgrade kit? If this works then its a very large cost difference.Cheers

Jono

-

Haven't heard about the escort swap, would be intrigued to hear.

What does work is the mazda BA 323f v6 2.0 spindles. I think you can even fit mazda MPS calipers onto them. Some guy on club-323f has done it.

Never bothered with short shifters personally so can't help there!

-

So things have been progressing well with the engine tear down.

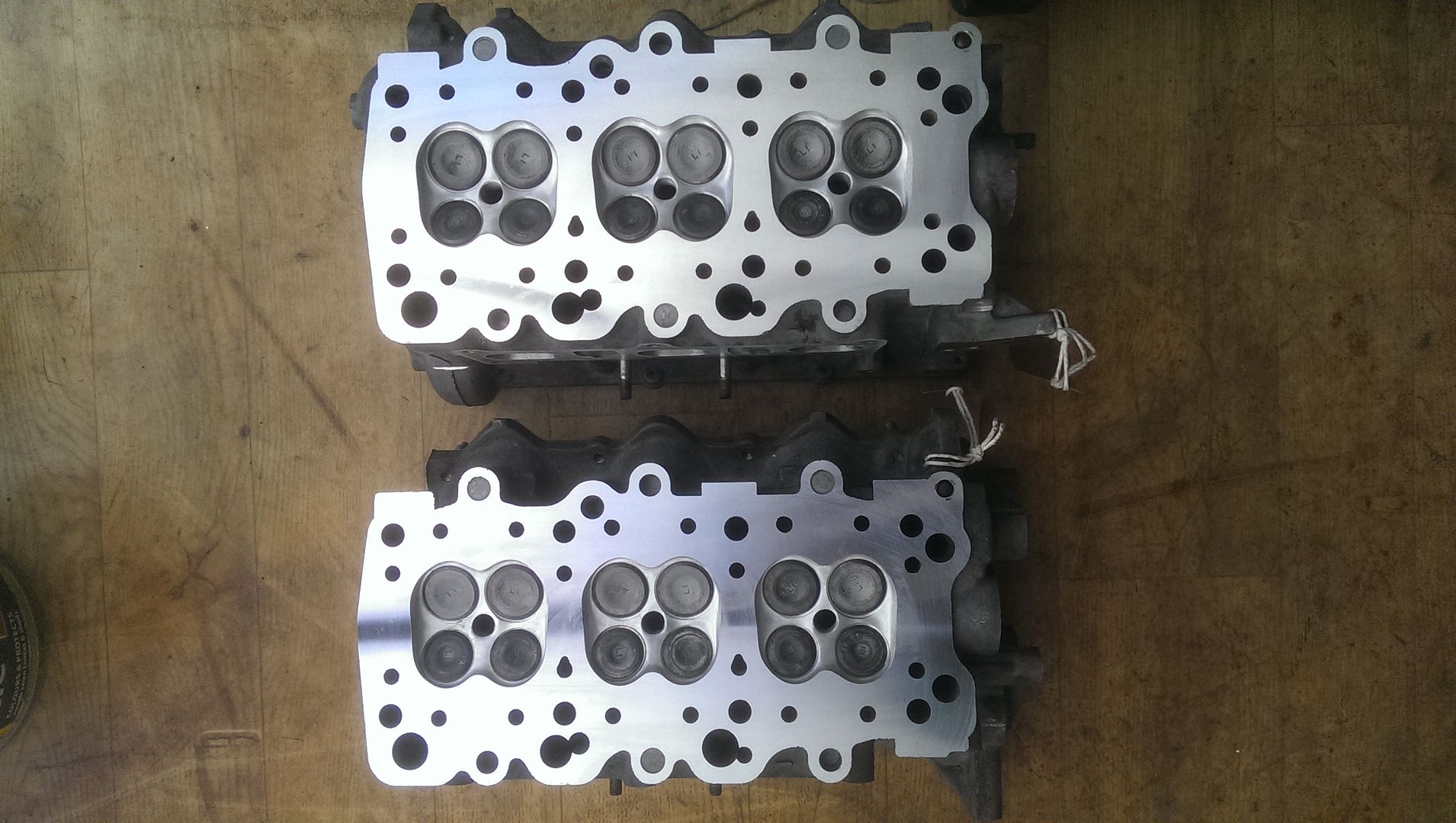

The heads have been completely stripped down:

And are now in with my engineering shop for port & polishing and a general clean!

The block is now nearly completely stripped, the only thing that needs doing is to pull the crank out, that can wait until I need to as I'm running out of space for all the parts I have lying around lol

Bye bye old friends:

Nothing to see here, for now…

All going well the new parts should be here within 2-3 more weeks :)

Jono

-

Woohoo! Good work. How do the crank journals/rod bearings look?

-

Bearings actually look ok but I have new on order anyway :)

Getting close to re-assembly which is getting me excited lol

Still plenty of stuff to do, and a little research and more stuff to buy.

Jono

-

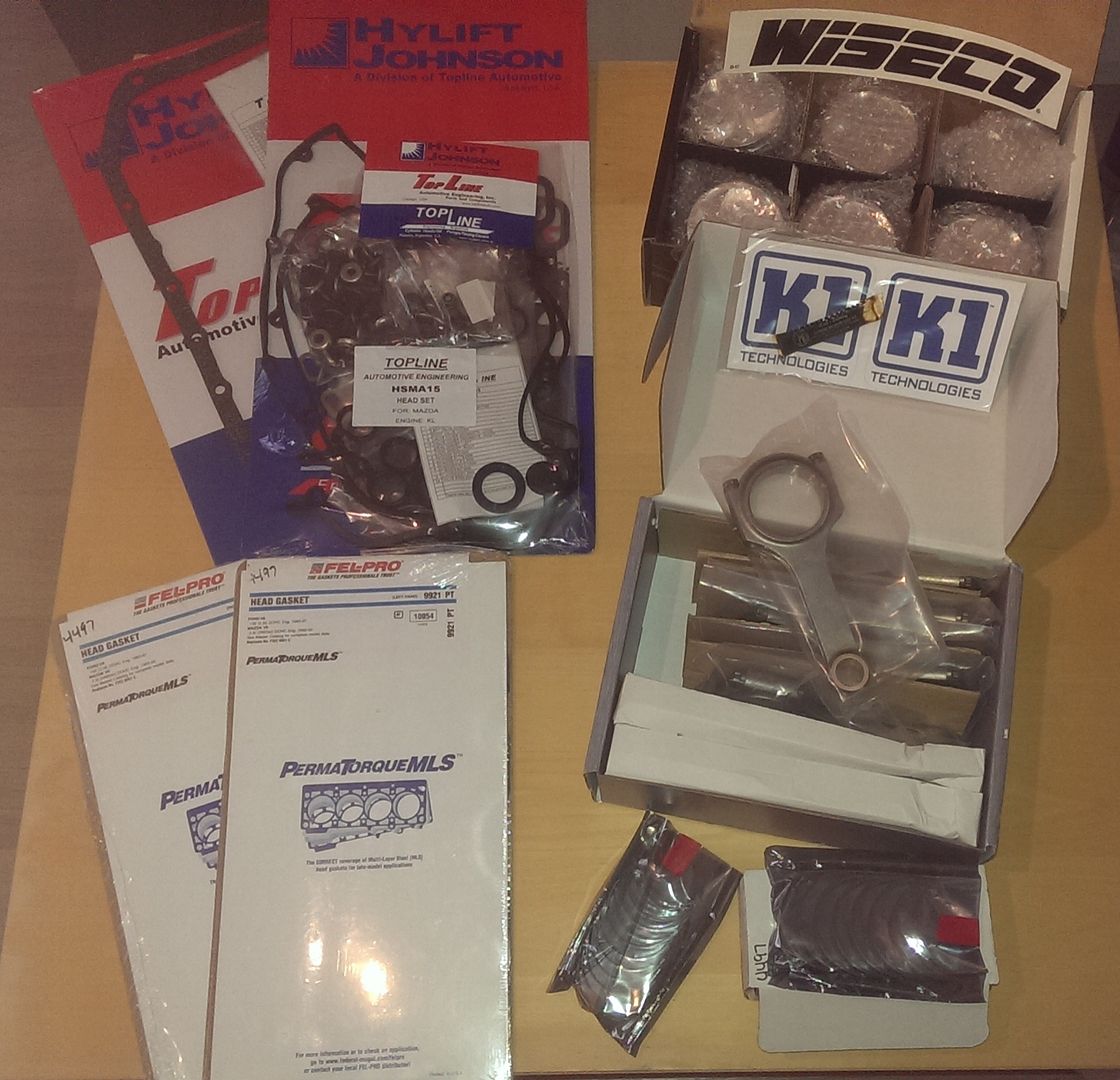

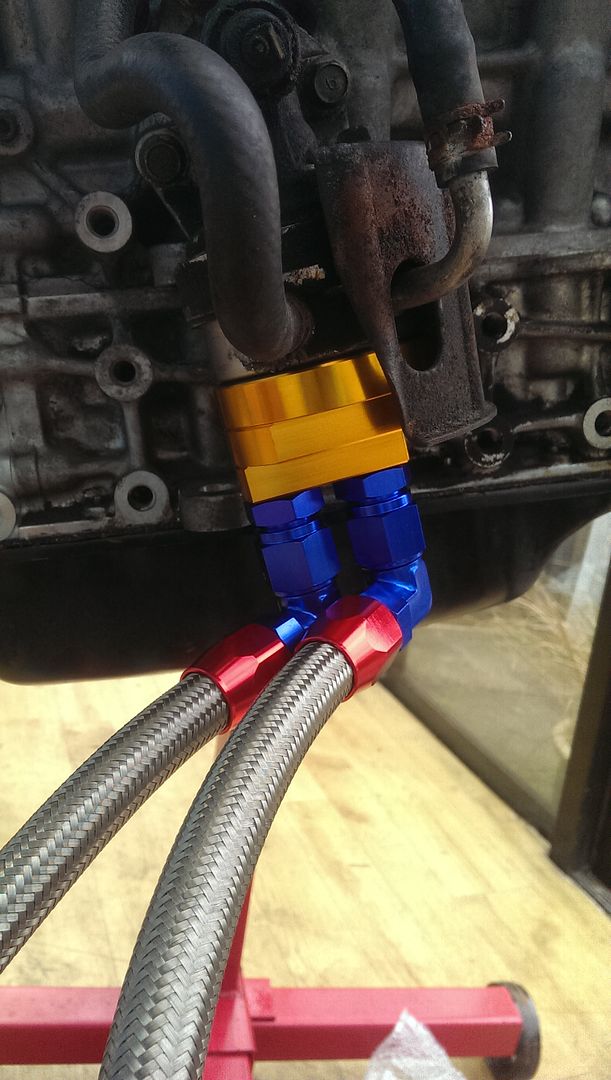

Just taken delivery of these bad boys:

Fun times ahead :)

Just need to find a big break upgrade option now!

Jono

-

Even more stuff arrived today :D

Some shiny new Wiseco 9.1 CR pistons to allow safer boost + higher boost 8)

Should be able to start rebuilding the block now…

All I'm waiting on now are the valves + springs etc, hopefully that wont be long.

Jono

-

great - stock bore?

-

Yep I decided to keep the stock bore, this means I don't have to make any changes to the vehicle registration (Given it was changed when I dropped in the ZE originally).

I did however get lower compression ratio pistons, will now be running 9:1 which is safer for boost and with the built internals I should be able to get some decent power out of it :D

Just waiting on the final few parts, should hopefully have some machine work on the block next week then I can start rebuilding from the bottom up!

Jono

-

You need to be sure you have right block (with right dimension on every cylinder) and correct crankshaft.

Install the KLDE springs and retainers if you have everything disassembled.

Best luck!

-

Yep, I measured the cylinders before ordering the pistons, also the block and pistons are going to my machine shop this weekend and they will double check all the measurements, the worst case is that I spend a bit more and have the block re-sleeved - but shouldn't be necessary.

Springs and retainers is a little more complicated, I had new valves, springs, retainers etc on order but they still haven't turned up. So I'm going to keep the stock for now and will replace them in the future. I do however have the springs from the KL-101 block which I understand are better.

Jono

-

Just thought I would post a quick update on the re-build progress.

So the engine has been out for about 8 months now!

This week I finally collected the block + crank, pistons etc from the machine shop… very exciting stuff :) as this means I now have everything to start rebuilding it!!

So, why so long you ask... well the new pistons I ordered (which took ages to arrive) would have been fine, however the machine shop noticed the clearances on the cylinders were a little bigger than expected. Thus a rehone would actually have put them outside the tolerance I need. We looked into a re-sleeve, it turned out that there was already sleeves in the block (I'm unsure if this is factory or perhaps re-sleeved in a previous life), the guys found it hard to find the exact matches, the ones in there were flanged - this was a problem apparently. After a large amount of research and thinking we eventually decided to over bore and buy replacement pistons to the new size. Again this took a number of weeks to deliver from Wiseco. Once they arrived the guys over bored the block then re-balanced everything (Unfortunately they had already balanced the old ones so I had to pay double for the balance work :().

Now that all the machine work is done I can finally start to get this thing back together, a couple of rogue bits still to find/buy:

- Megasquirt Unit (+Harness - If I go for the MS3)

- Up-rated fuel pump

- Up-rated injectors

- Power Steering Pump bracket + tensioner

- Head bolts (These have been on order from fordprobestore.com but I have had 2 lots go 'missing in the post', Mark used to be pretty good but I am starting to have doubts)

I also have a spare set of 84.5mm 9:1 CR Wiseco Pistons, they have been balanced so have been drilled but if anyone is interested then let me know. Will advertise them at some point.

Jono

-

Any updates Jono? Sorry to hear about having to oversize :(

Shaping up to be an epic build though.

Yea FPS was pretty disappointing last time I used them.

-

Yeah sorry for the delay, various things have got in the way recently.

Oversize wasn't great, ironically I would have saved myself some money if I had just got the machine shop to order them in, oh well, lessons learned now.

Anyway, the build is finally progressing, the new pistons/con rod assembly's are installed, bottom end is back together, the heads are back on and the cam's back in.

A couple of little things that have been a pain:

Unfortunately I am missing a water pipe gasket from my kit so that's going to have to be ordered this week, hopefully I can get one quickly.

The machine shop damaged one of the head locating pins when they removed it to skim the head, this took a few weeks to get from Mazda.

I've had to get a fair few non shelf parts from Mazda - my local main dealer has been pretty damn good at getting all these parts which has me pretty impressed, even if a few of them have had to come from Japan!

I decided to get a new oil pump & water pump, given the effort/cost already in this I thought its better to start with fresh new pumps.

I managed to find a full set of red top high flow injectors on ebay, I need to test them but I'm hopeful this will have saved me about 600+ for a new set.

The cam covers are going off this week to get sandblasted then painted - I have something special coming on that front :)

All going well the engine should be fully assembled by the end of August with the aim of getting it installed early September (my Mrs is desperate for the conservatory back which is currently a surrogate workshop lol)

There is still loads of work to do but I'm happy things are finally moving!!

Also, I have a megasquirt unit and I'm going wasted spark, I have ford gen 2 coilpacks, unfortunately our leads are the wrong type for these so I'm probably going to have some made up.

I will post some pics soon.

Jono

-

Sounds like you're doing everything right! Conservatories make the best workshops, so much light :)

Same coilpack I used pretty much. you can force the leads on by pushing hard. It's not ideal, but it did survive my turbo antics! Let me know who you use for the leads, I really should do the same.

-

As promised, here are are a few pics from the rebuild so far :)

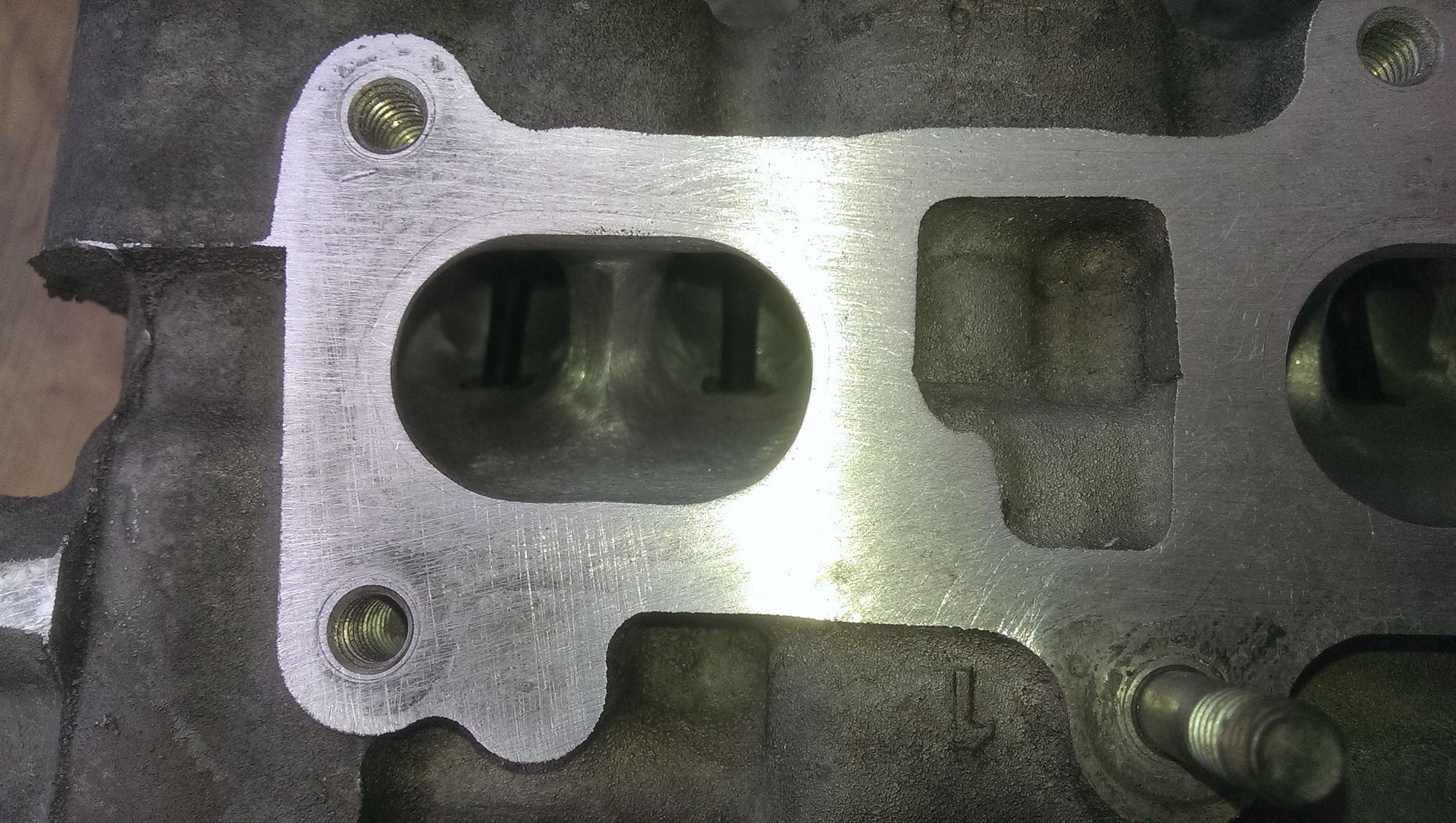

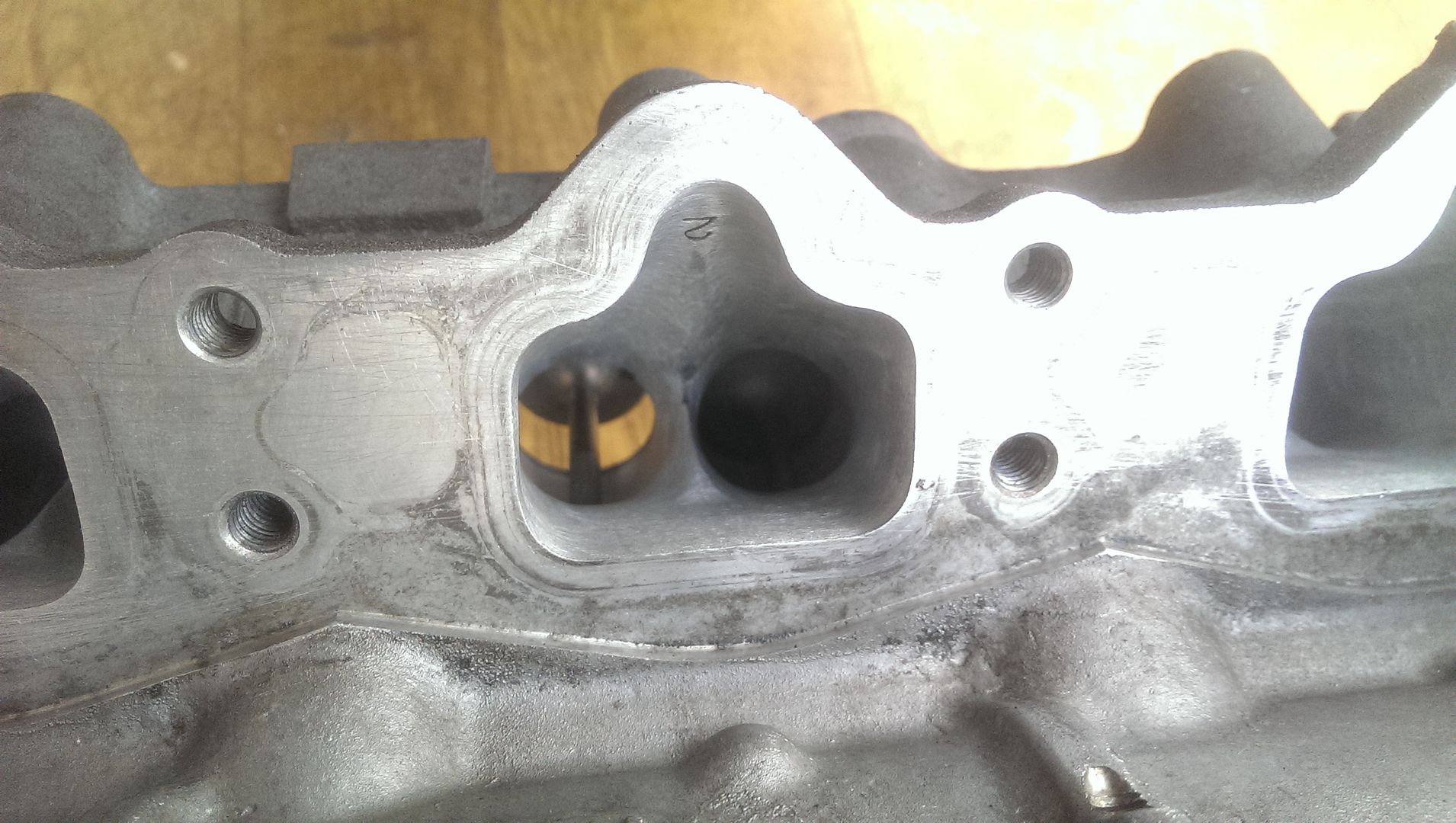

Fresh Heads (Port & Polished)

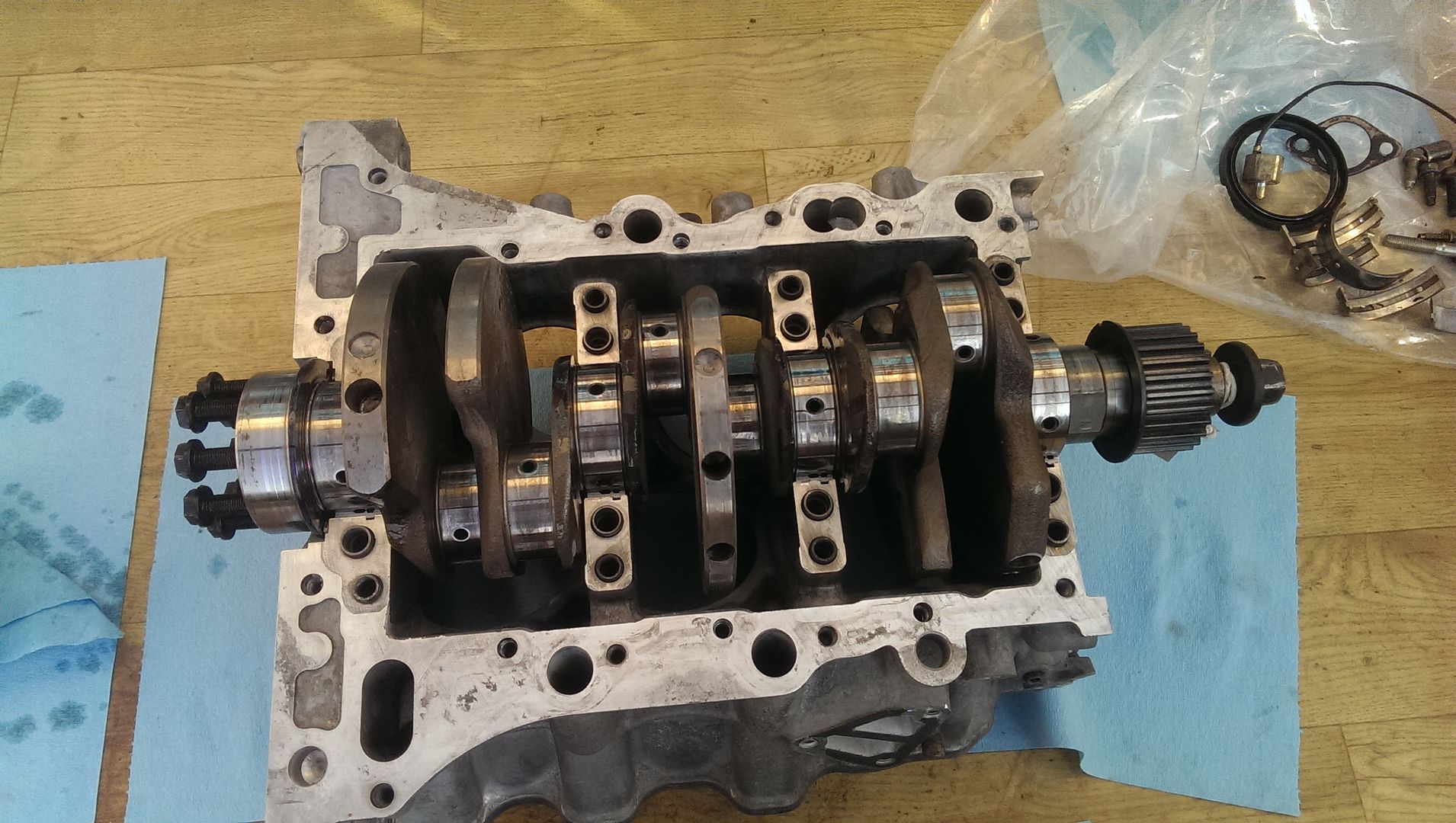

Block and internals back from machine shop

Crank back in

Con rods and pistons

Performance head gaskets

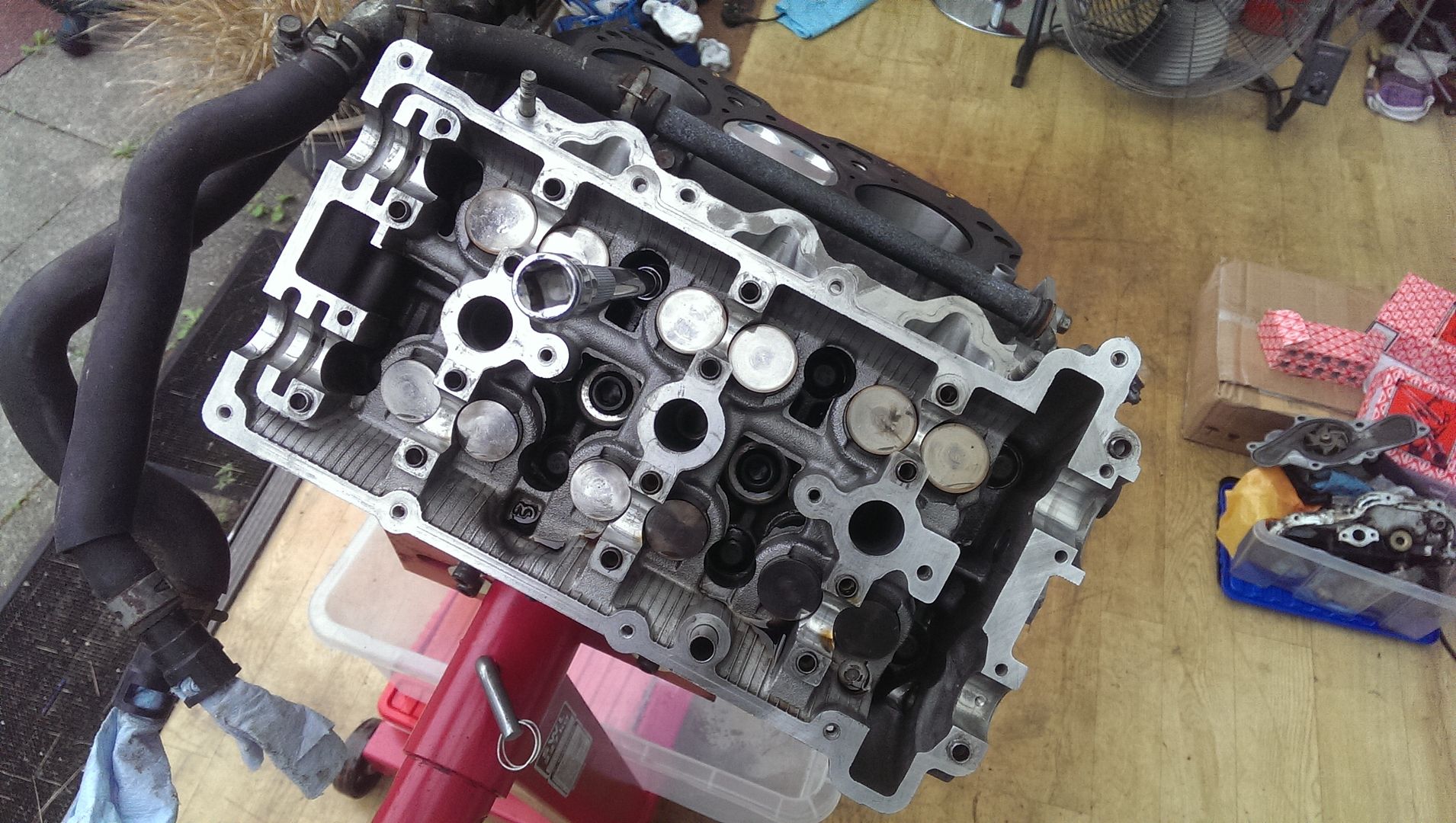

Heads going back on

Pretty lol

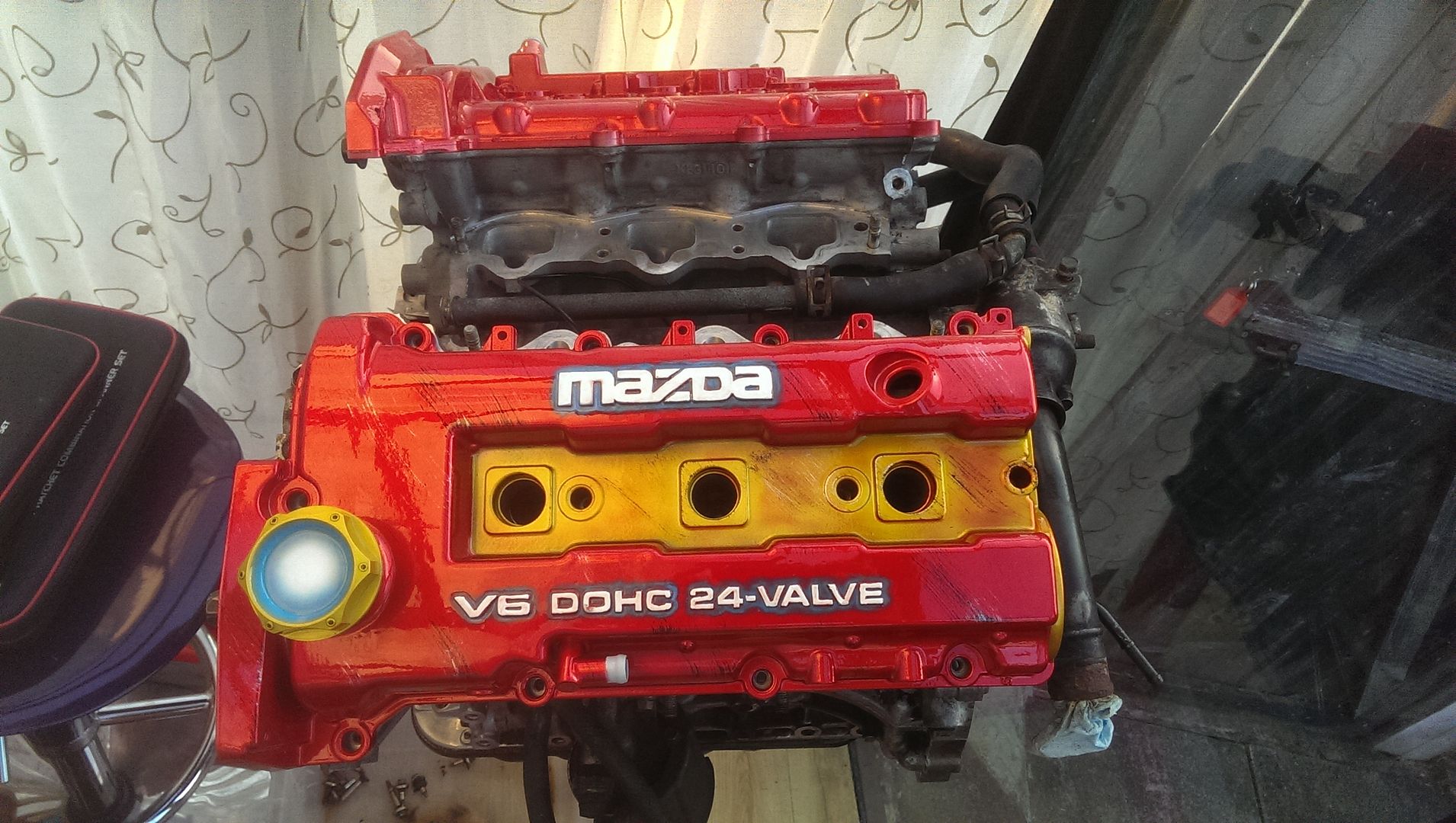

Freshly airbrushed cam covers

Firstly, can I just give credit to Foz's Airbrush Projects for doing the art work on the cam covers, I am really happy with it, designed to be distressed iron man like with an arc reactor :)

Check out his work: https://www.facebook.com/FozAirbrushProjects/

And thats where I am so far, hopefully I will have the belts back on in a week or two.

Jono