Sam's Proper MX-3 - LT Turbo project *Parting out*

-

Pretty sure you need one of them funky external wastegates I don't got.

-

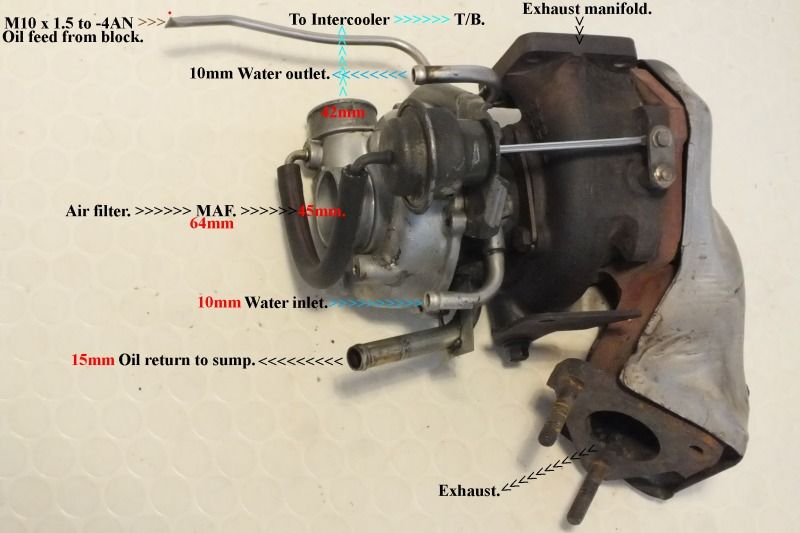

IHI Turbo meets B6 explained.

Existing oil feed , Mazda knew this engine was for boosting!

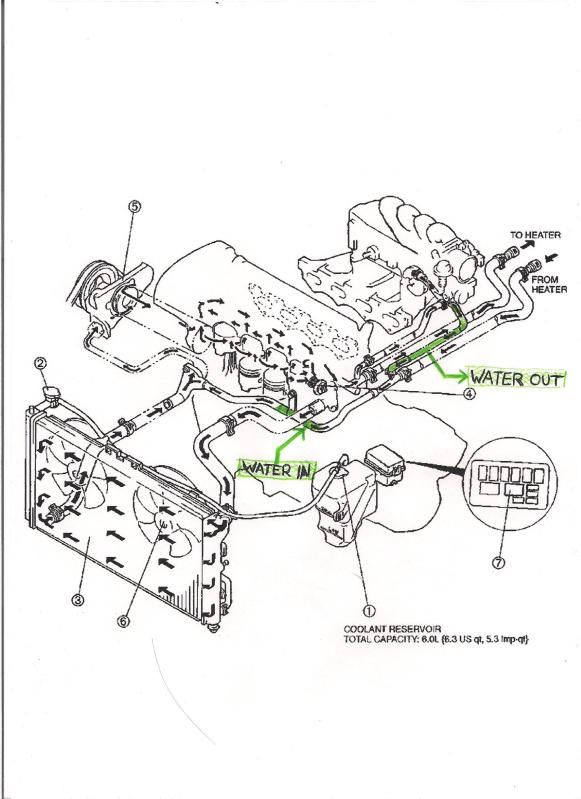

Proposed water tap into the system.

-

Test fitted the Intercooler to the car this morning. Went in as planned without removing the bumper :D :D :D

Worked out how much more IC piping Im going to need, the exact sizes for the water tap T pieces and the length for the oil line needed. Getting a bit excited now even though there is still quite a bit to do & buy….

-

what size pipe is the intercooler piping as i have loads of shiny ic ally pipeing

left over from my ic setup i can do you a good deal on it if your interested?

-

Im using 42mm jay, its cool mate I've sorted it, cheers though.

-

My 10mm "water out" Y piece arrived today, also found a bung for this which means I can fit this inbetween the throttle body and main heater matrix hose now in prep. and check for any leaks now rather than later.

Along with the 16x12x16 "water in" T piece to be inserted into the metal water pipe running along side the exhaust manifold by cutting a piece out and using some pieces of 5/8" (16mm) rubber heater hose.

This may also need a 12-10mm elbow reducer onto the turbo.

-

Oh me oh my. Havn't been on in a while and went straight to your log hoping for good things and this is what i see. This is exciting.

-

Yeah Buddy! Its moving on nicely…A few more parts bought this week...

9mm oil breather filter for on top of rocker cover.

And most importantly, a boost gauge in 37mm micro digital format!

-

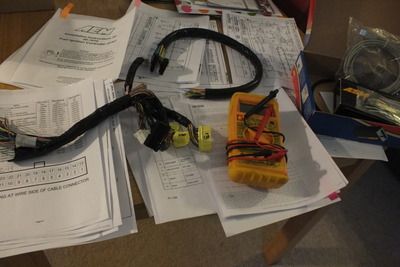

So this is how I spent my Saturday evening with a mate & some brews doing more research into how we are going to hook up the AEM piggyback.

After a good few hours we came to realise that all the B6 wiring diagrams including the Miata ones are different to the ECU plug we had sitting next to us! Ideally would like the B6 BF schematics but these do not seem to exist online. So its going to mean finding all the relevant sensors in the engine bay (Injectors, TPS, cam/crank angle & MAF) then tracing them back to the ECU plug with the multimeter just to make dead sure, shouldnt be too much of an issue just more work than we had hoped for. Atleast the MAP is easy to tap into!

-

Well shit was going great guns till I took the turbo outside to do some more workings out and discovered its cracked through the exhaust housing into the penny valve area..Its goosed basically ffs bought that in good faith aswell :x

So now I got to reconsider my options, seeing as there is hairline fracture in the 323 manifold I could be looking at the weld your own Turbo manifold kit

from the US for 200 dollars meaning I can use the common as muck T25/T28 instead of the rare VJ series turbo. That would also mean I could upgrade to the GT series roller bearing turbo later on, ah man this is a hard bullet to bite right now!

-

Awh man, I'm sickened for ya. This is the typical shit that happens during builds like this I guess. Keep the faith! That momo of yours deserves powah! I might be able to get you a second hand t28 for cheapish, WKD Imports Drift team is from my area so guess they've a few lying around!

-

Cheers bro I know It is a complete pisser but it's kinda making me more determined now than ever to get some serious powahhh to this behatch.

Im just waiting to here back from http://jgsturbo.com/index2.html about shipping for the kit and if its not extortionate then I will probably go for that> not that I have alot of choice,lol

For ref. http://www.miataturbo.net/diy-turbo-discussion-14/diy-manifold-66261/

-

I may have found a way round it to keep the 323 manifold and use a T28 at the same time, tbh I really think that mani. is too rare to waste you cant beat a cast one as stainless is so prone to cracking.

The solution could be a adaptor flange as I happen to have a T25 gasket lying around I thought I would test my theory against the VJ gasket on the bottom. As long as its shorter than this Im hoping it wont sit the turbo too far down. Have a 8mm steell T25 & IHI laser cut flanges coming now and will have a go at machine up from billet steel or use some tube to make the adaptor.

Hope this works then I will only have to fork out for a turbo

:D

-

Two meaty flanges mwahahaha

and a pukka pipe which now need take offs for a dump valve and the IACV

Been bidding on a few Turbos, but keep missing out to snipers gggrrrrr but Im hopefull to win one soon then I can progress some more

-

Sam, do you have a BOV to use?

encase you do not I have a stock OE BOV off of a Ford Probe I can give you, just PayPal me shipping.

I used it on my B6 for years and was perfect. it is 2" diameter pipe I believe and it is a recirculating, but it always had a nice pffuushsh kind of sound. Let me know :)

-

No don't got one yet, was thinking full atmos. just for a laugh to begin with then recirc. when I wanted to be a bit more stealth.

Im interested thanks could you post some pics.

-

Bar a little bit of a surface grind to the flanges the IHI to T25 adaptor block is complete :D

Final height is 38mm

Other good news! won what the Fella reckons is a recently refurb. Garrett T25 (new bearing, seals and wheels) for 75 quid on Sunday night, looks a bit ropey on the outside so will clean it up when it arrives and sort out new water/oil ports for it, and also "clock" it by rotating the housing's to get the oil drain right and the bottom and the turbine housing pointing somewhere nearer to the intercooler :D

-

75 quid? Nice job! Good to see progress on the turbo part of this project. Have ya figured out how to wire up the AEM piggyback?

-

Yep worked out to be 97 pounds delivered (My keyboard is all fuct up wont let me do the pound sign)

Aye we know how to wire it up its just a case of finding the right wires now, as no wiring diagrams exist for my car not even on autodata! will mean a day or two with the multimeter out in the car. I got to help my wiring man fit some coilovers to His Ibiza cupra then we should be on it.

-

Sam a thought on when you wire your piggyback up. rather than wire up the piggy back to the Throttle Body for values, one thing that tends to work better is to wire in an RX7 MAP sensor and run your piggy back off of the MAP. it give is a lot more adjustability, and functionality out of the system.