Sam's Proper MX-3 - LT Turbo project *Parting out*

-

Cheers Jay I cant take all the credit for it though my homes Peter N Younger certainly knows His way round a wiring diagram or three 8)

007 (psi) license to turbo & kill clutches…

-

brilliant work! Hope you've got notes of everything. Is it actually running the car now then? Fuel / spark?

-

Cheers Marc! Yeah got oodles of notes that I need to make into a nice XL document or something. It was actually a nice enjoyable wiring day, usually having worked on French cars there a complete 'mare wiring, but nearly all the wire colours matched the schematics so that was a massive help :D

It is fully running all the time now with ign. on but my understanding of it is that all the fuel/spark tables come set to 0 as default so without changing any of those it wont be affecting anything as such just yet> Just running in harmony with the stock ECU :D

-

Been busy lately configuring & clocking the turbo so the compressor housing points more towards the intercooler. It does spin without taking the circlip off just needed a few tap with a rubber mallet to get it going. This does now mean a new wastegate actuator though which is on order from the states, went for a 10psi unit with an adjustable arm to be able to set the spring pretension and a custom bracket.

Have also bought 2 x M14x1.5mm banjo bolts with a 10mm hose tail to use for the water, but I also managed to redrill the VJ water connection pipes from 12 to 14mm so I can use them if needed too. Oil drain I did modify then realised it was the wrong size hose connection so an oil drain kit with a 45 degree 12mm hose tail is on order along with 1/2 meter of stainless steel overbraided hose to connect to the sump and a 57mm-64mm silicon reducer for the air intake. also got an issue with the compressor flange to overcome as the pipe that came off the 200sx points in the wrong direction

so that will need a flange buying for or the existing one being used but with a more favourable direction on it.Will edit pics into this post as things start arriving :D

Compressor flange issue sorted! cut off both ends of the elbow and machined them flat again ready for welding.

Rear of Turbo water connection, 90 deg. bend to hopefully miss actuator arm.

57mm-64mm silicon reducer fits perfect to go upto the MAF

10psi wastegate actuator, with mock up of bracket needed.

Had a nice delivery from Oz. this morning, my adjustable wastegate bracket>

choice of 2 oil drain 45 degree bends now as the new flange fits the old piece I bought, last picture is the new 45 degree pieces I bought pictured with the 1/2" stainless steel braided hose.

Oil feed line parts:

M10 > 4AN oil connector for turbo feed out of block.

By dirtfox at 2012-09-154AN 90 Degree speed flow stealth elbow.

By dirtfox at 2012-09-154AN stealth black nylon braided line.

By dirtfox at 2012-09-15M11 > 4AN with 1.5mm restrictor for conection on turbo.

By dirtfox at 2012-09-15

-

With warnings of a few car break ins round my area I wanted to get the AEM tucked out the way incase it was mistaken for amp.

Managed to squeeze it in behind the stock ecu and stuck it to the floor with heavy duty velcro, comms lead routed up to the back of the glovebox also.

Will put the side panel covers back on as soon as I have found the fixings again, as there are also some new MOT laws in force now I think concerning ecu tampering?!

-

I would be lost with adding a turbo to anything thats where my knowledge wall is, looking and look forward to seeing this done soon

Hope you are coming to HJC summer show in 2 weeks on the 19th :mrgreen:

-

Once you've swapped in a Turbo engine it kind of gives you a good idea of what is needed, and now its time to learn from that and do this one even better :D This is even more involved though!

It won't be done anytime soon, as there is still alot to custom fab. and more bits to buy:

Clutch.

Downpipe flange.

Oil feed line.

injectors.

lambda boss.

few more silicon joiners now the turbo has changed.

lots of various hose clips.Still to sort:

fit clutch.

fab. up wastegate bracket

make downpipe.> not my favourite job, currently looking into a chop saw/hard disk cutter arbour for stainless! either that or its going to a hacksaw job:(

swage/bead alu intercooler pipes and maybe a ceramic coat.

Iintercooler mounting bracket + weld outlet/inlet back on.

IACV spigot on boost hose.

recirc valve spigot on air pipe.Then the kit should all be ready to just bolt on :D Will have to see about the 19th Keith.

-

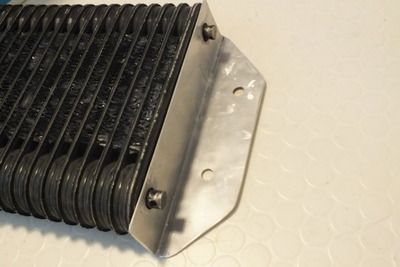

Designed the intercooler bracket monday and made it today,

it will bolt to the upright holding the bonnet realease catch with plenty of rubber grommets/washers so its got some movement as not to stress the end tanks.

Im thinking body pins to attach the bracket to the 'cooler?!38mm-51mm 45 degree silicon reducer elbow to connect lower intercooler pipe to cold pipe upto throttle body.

all silicone hose bought now!

-

had some great news today> My insurance renewal came through and its gone down for once! manily due to some points finally coming off, now paying 420 quid fully comp through Flux.

Some parts that I have ordered were not compatable, mainly the oil drain return flange did not fit up with the 45 degree piece I bought, even though they were both 1/2" NPT :shock: So I have had to start again on that, now waiting on them too arrive from Germany and Canada!

Been out and about with the camera, really pleased with this one and even happier when the wife presented it to me printed out on canvas for our second wedding anniversary.

This is an old one that I have remastered in photoshop!

-

Cool shots there, Sam.

The way your car sits really is incredible, the wheel size and the lowz really makes it look so good, especially with the smooth bodywork. Really is one of the most visually appealing 3's out there, and always comes as a breath of fresh air compared to the styling of most 3's on here and the .com (mine included!).

-

Thanks Jason appreciate what your saying and yeah you are right as alot of the comments I get when this car has been shown on lots of other car forums are mostly about how they usually don't like the MX-3 but this one they do or it has changed there opinion on it. It is probably the lowest driveable '3 in the world right now :shock:

Have also had some interest and possible coverage from a magazine but they want power figures from after the turbo is fitted, plus I will want to get the paint and bodywork right upto scratch which is the next mission after I have bought a few more bits for the install.

Sussed out all the parts needed for the oil feed line yesterday and flushed out the intercooler yesterday also got all the parts ready for weld as our guy is back at work this week, then I'm off to Greece next week for 10 days but when I get back it will be time to save for a paintjob and the wheels.

-

I do love your 3 fox, have to admit, very temped but the roads near me are just way to speed bump heavy for me to get it out of a 3mile radius of my house. :( bastards.

-

What magazine is it, Sam? If I went any lower on my roads, there'd be no car left to drive in no time! The V6 at least don't have a very low-friendly undercarriage, especially in Ireland! Seems to be a lot of protruding bits and pieces!

-

Yeah who ever came up with the idea for speedbumps wants shooting! I mean they spend all that money trying to make roads as flat as possible then fuck it all up with massive lumps :?

Was driving in London yesterday luckily we took the wifes car, jeezuz some of those bumps you NEED a Chelsea tractor to get over!Will raise her a little anyway soon as winters coming and I got to pop over to the I.O.W. soon to visit Gulfy for some paint.

I seem to be catching a lot on the bracket that holds the cat up, pretty sure its coming loose now from all the hits,lol and would imagine the front subframe is not that great either! Its a shame that to make it look that good you have to compromise some performance.

and I swear Mazda where going to make the bumper like I have with filling in that top hole (The rest of the range are > MX-5, RX-7) but then had overheating issues with the V6 and had to address it!

-

Seeing as you wont see all this work that's gone into this cross-over pipe once its installed though I would share a pic now.

Was quite amusing today as it actually took 3 people to swage the curved end as we had to manually wind the belts of the lathe

while someone else crushed the bead in and I manipulated the pipe round and round, well pleased with hows it turned out and chuffed

I managed to turn the 5mm boost gauge spigot from a piece of solid square bar held in the 3 jaws!

All the welds were then pickled in acid to remove the scorch marks and washed down with water and neutralizing solution.25mm dump valve, 18mm IACV & 5mm boost gauge spigots on the cold pipe done.

25mm silicone end caps to block off recirc valve ports for now.

By dirtfox at 2012-09-15compressor outlet welded and cleaned.

-

Good observation on the bumper, never crossed my mind but I reckon you could be onto something.

I know feck all about metalworking and welding, but it sure does look good!

-

nice work sam

-

Thanks Lads! back from holiday now, so back on with the fun!

-

Been quite busy recently decorating some of the flat which involved moving my 400L aquarium! but with the aid of some youtube videos I have managed to construct the oil feed hose today for the turbo out of the parts I bought, unfortunately the union that goes into the engine block I got wrong as its not M10 x 1.5 or x 1.0 so I have 1/8 BSP and NPT straight unions coming so will update the info further up the thread with the right info for yo'all.

-

So one thing that is different between our B6DE block and the B6T are the oil pan setups. Ours has the dinky steel pan with the block strengthener above it where the B6T has a full cast aluminum pan without the extra block support. Are you just drilling and tapping your existing pan?

Great parts thus far!